Optical Polishing &

Lapping Services

Our specialized technology achieves nano-level accuracy with surface roughness as low as Ra 1 nm, dimensional tolerances precise to ±0.5 μm, making us the partner of choice for industries where extreme precision is non-negotiable.

Industry Leaders in

Ultra-Precision Surface Finishing

In today’s competitive high-tech manufacturing environment, surface quality and precision often mark the critical difference between success and failure. Since 2005, YISHUN Optical has been dedicated to providing industry-leading optical polishing and lapping services, solving the most challenging precision machining needs for clients worldwide. Our specialized technology achieves nano-level accuracy with surface roughness as low as Ra 1 nm, dimensional tolerances precise to ±0.5 μm, making us the partner of choice for industries where extreme precision is non-negotiable.

Are you facing these challenges?

- Optical polishing components requiring extreme flatness and surface quality

- Complex geometries needing precise polishing

- Ultra-precision surface finishing requirements for hard materials

- High-volume production needs under strict tolerance requirements

- Processing difficulties with special materials like sapphire, silicon carbide, or quartz

YISHUN Optical has the advanced equipment, technical expertise, and experienced engineers to provide comprehensive optical polishing and lapping solutions, no matter how complex your project or how stringent your requirements.

Understanding Our Core Services

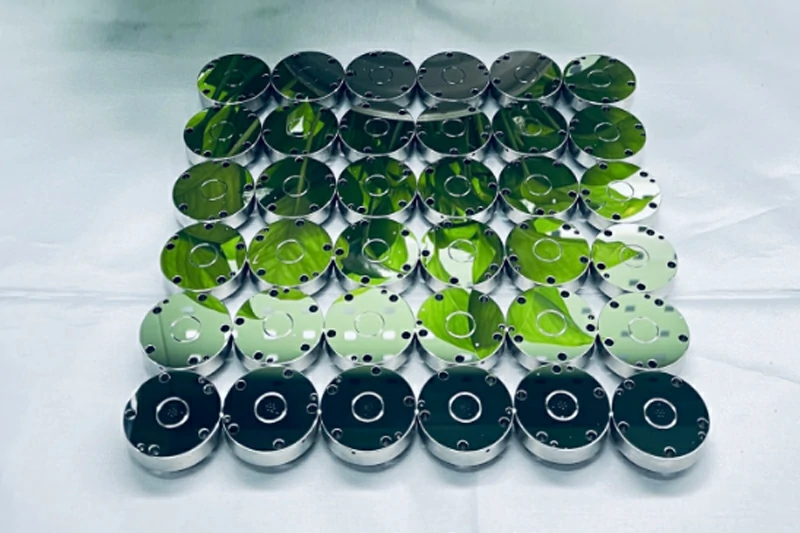

Precision Polishing Services

Polishing is a process that uses polishing compounds to remove surface irregularities and create a smooth, reflective surface. At YISHUN Optics, we utilize advanced technology and equipment to process a variety of materials, including metals, ceramics, optical glass, and plastics, providing precise polishing solutions for industries such as electronics, optics, and aerospace.

Our polishing capabilities:

- Surface roughness down to Ra 1 nm

- Flatness precise to 0.1 μm

- Dimensional tolerances achieving ±0.5 μm

High-Precision Lapping Services

Grinding is a specialized process that ensures the surface of metal parts is smooth and uniform. This process can also create fine or mirror-like optical effects on certain metals.

YISHUN Optical has been providing precision lapping services since 2007, specializing in high-accuracy optical and mold components. Our lapping processes achieve:

- Flatness precise to 1 μm

- Surface with Pear Skin Finish/Frost effect

- Dimensional tolerances achieving ±1 μm

Distinguishing Between Polishing and Lapping

While both polishing and lapping are used for surface refinement, they differ in technique and outcome:

- Lapping: Involves two surfaces rubbing against each other with abrasive material in between. This technique is often used for achieving extreme flatness and is ideal for applications such as lens manufacturing, mold finishing, and optical component processing.

- Polishing: Use soft materials such as wool balls or cotton, combined with fine abrasives, to achieve a mirror-like shine. It is typically used for final surface finishing to enhance the smoothness and gloss of the material.

In many cases, both lapping and polishing are used in sequence to achieve the required surface precision.

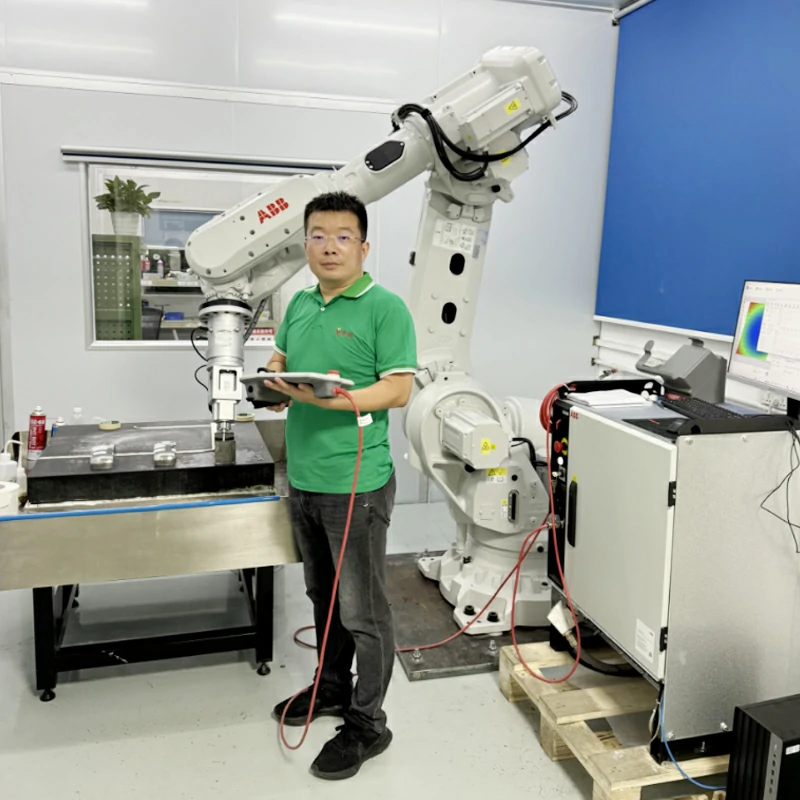

Our Technological Advantagesents

YISHUN Optical employs multiple advanced processes to provide the optimal solution for your specific needs.

Polishing, good precision, high brightness and consistency

Three-axis, five-axis, six-axis polishing and grinding, ultra-precision machining and other processing technologies

20 years of polishing industry experience team

Materials We Process

YISHUN Optical has expertise in handling a wide range of advanced materials:

Metals

- Stainless Steel, Superalloys, Copper, Titanium

- Aluminum, Tungsten, Nickel, and more

- High hardness alloy steel HRC90 or above Tungsten steel High purity oxygen-free copper Mirror aluminum

Plastics

- PEEK (Polyether Ether Ketone)

- PMMA (Polymethyl Methacrylate) and more

Application Areas

We process a wide range of components used in advanced industries

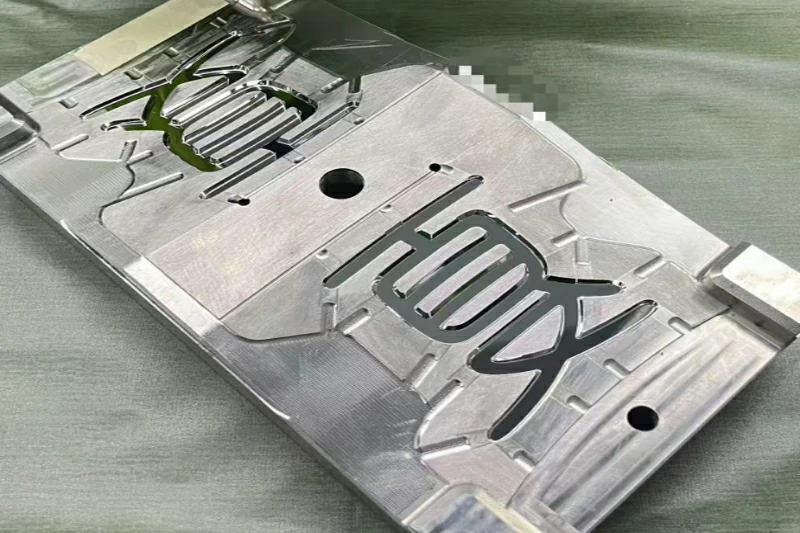

Optical mirror plastic mold

Optical mirror plastic mold refers to the mold used for plastic products with optical-grade surfaces (usually requiring surface roughness RA < 0.01um, or even reaching nanometer level).

Industry Solutions

YISHUN Optical’s ultra precision machining services meet the needs of multiple industries

Why Choose YISHUN Optical?

Advanced Technology and Equipment

- Latest ultra precision machining machines

- Advanced metrology and quality control systems

- Environmentally-controlled clean room facilities

Material Expertise

- Experience with a vast range of materials from soft metals to hard crystals

- Specialized knowledge to address unique material challenges

- Comprehensive understanding of material characteristics

Quality Commitment

- ISO standard certifications

- Comprehensive testing and verification

- Rigorous quality control processes

Extensive Experience

- 20 years of ultra precision machining experience

- Success stories across multiple high-tech industries

- Expertise in solving complex machining challenges

Customer-Centric Approach

- Customized solutions tailored to your specific application

- Responsive service and flexible production capabilities

- Long-term partnership relationships

How Our Customers Benefit

Enhanced Product Performanc

Our ultra-precision surface finishing translates directly into better product performance, whether it's optical transparency, electrical performance, or mechanical durability.

Cost Reduction

By manufacturing precisely the first time, we reduce scrap rates, lower rework costs, and extend tool life.

Competitive Advantage

When your products showcase the highest quality surface finishing, you stand out in the marketplace, attracting high-value customers and building a reputation for excellence.

Complex Challenge Resolution

Our expertise enables you to develop and manufacture innovative products that were previously impossible due to surface finishing limitations.

Get Started with Your Optical Polishing and Ultra Precision Machining Projects

Ready to take your optical projects to the next level? Yishun Optical is here to support you every step of the way. Our team is dedicated to providing a seamless experience, ensuring that your optical components meet the highest performance standards through our expert polishing and ultra precision machining services.