Trusted by Global Innovators

Our Services and Capabilities

Yishun Optics provides comprehensive professional services to meet the needs of industries that rely on advanced optical components. Our core services include high-precision optical polishing, grinding, and ultra-precision machining, as well as custom solutions:

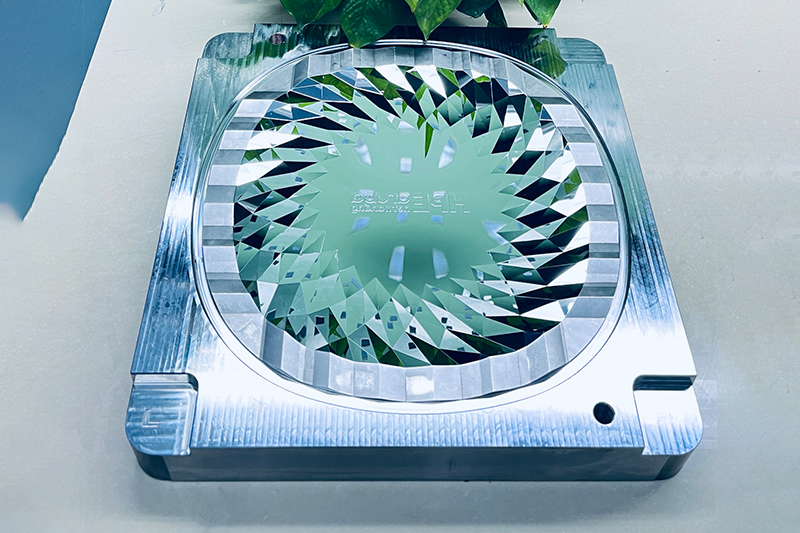

We provide specialized polishing and lapping services to achieve optical-grade surface finishes with roughness as low as nanometers. Using techniques such as magnetorheological finishing (MRF),ion beam figuring (IBF)and chemical mechanical polishing (CMP), we ensure that optical components have superior clarity and light transmission properties. Discover our Polishing & Lapping Services.

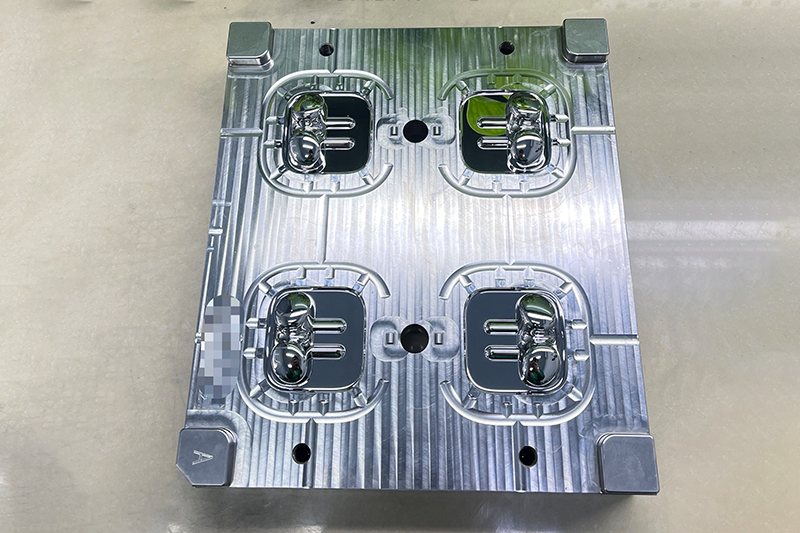

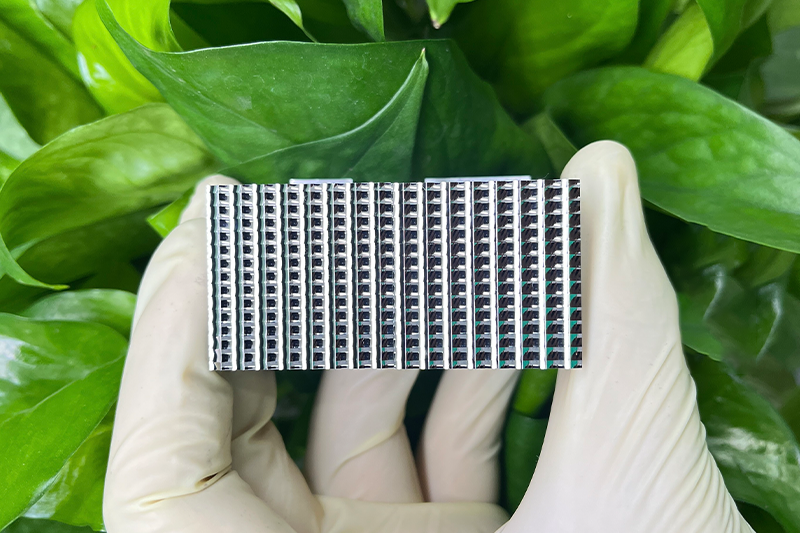

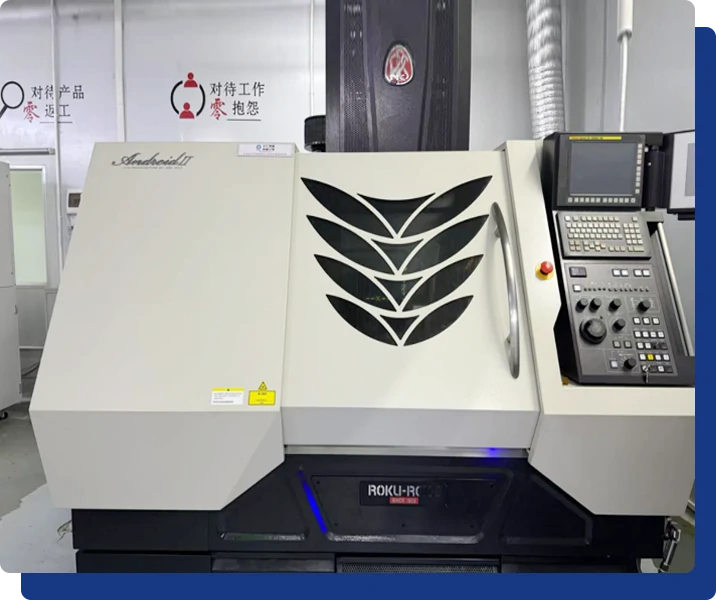

Our ultra-precision machining capabilities allow us to produce components with sub-micron accuracy, essential for the most advanced optical systems. Utilizing technologies like diamond turning, we cater to the stringent requirements of industries such as consumer electronics, automotive, and medical. Find out more about our Ultra-Precision Machining.

About Yishun Optical

Yishun Optical is a premier provider of optical mold design, manufacturing, and precision machining services. We specialize in delivering high-quality, customized optical solutions to clients globally. Our state-of-the-art facilities and experienced team ensure that every project is completed with the utmost precision and care.

Why Choose Yishun Optical?

In the optical industry, precision is paramount. Yishun Optical is renowned for its expertise in optical mirror polishing and ultra-precision machining. Our mission is to provide cutting-edge technology and customer-centric services to businesses worldwide. Whether you need high-precision optical mirror finishes for smartphone cameras or complex optical components for medical imaging devices, we deliver excellence in every project. Our tagline, “Precision Engineering for Optical Excellence,” encapsulates our commitment to achieving nanometer-level accuracy and driving innovation. Join the ranks of industry leaders who trust Yishun Optical as their optical partner of choice.

Confidentiality Agreement

Secure technical and commercial secrets to prevent leakage of core information and the resulting loss of competitive advantage.

Innovation

We stay at the forefront of optical technology, continuously investing in R&D to bring the latest advancements to our clients.

Reliability

Known for on-time delivery and staying within budget, we are a partner you can count on.

Collaboration

We work closely with our clients from concept to delivery, ensuring that their vision is realized.

Cost-Effectiveness

We offer high-value solutions that optimize costs without compromising on quality.

Industry Solutions

Yishun Optical provides tailored solutions for various industries, ensuring that each project meets the specific demands of its application. Our expertise spans across the following sectors

Our Technological Edge

At Yishun Optical, technology is at the heart of our success. We invest in the latest optical engineering tools and processes to ensure unparalleled precision and quality:

Ultra-Precision Machining

Employing single-point diamond turning (SPDT) and ion beam figuring (IBF) to achieve surface roughness as low as 1 nm.

Advanced Design Software

Utilizing Zemax and Code V for optical simulation and SolidWorks for mechanical design.

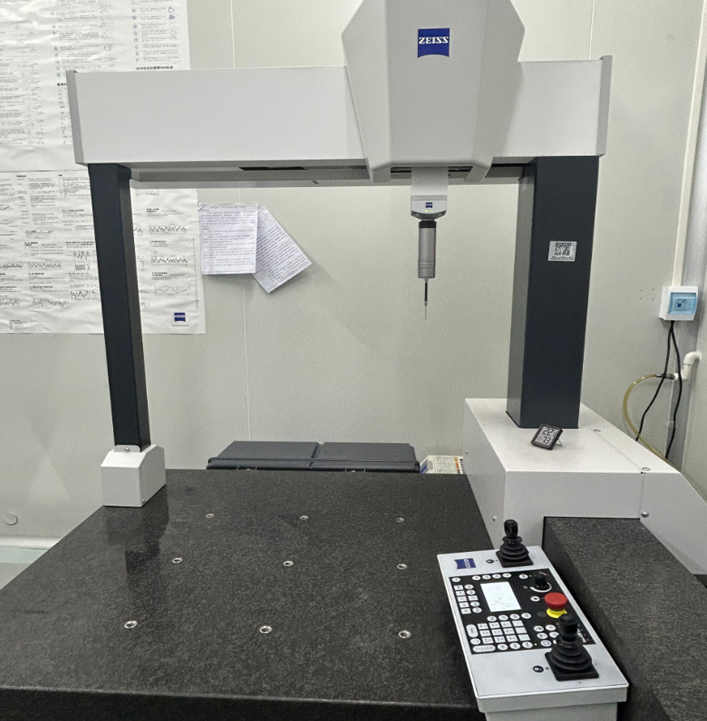

Stringent Quality Control

Using metrology tools like Zygo interferometers and atomic force microscopes (AFM) to ensure every component meets industry standards.

Customization Capabilities

From prototype development to mass production, we offer flexible solutions to meet your unique needs.

Put your parts into production today

All information and uploads are secure and confidential.

Voices of Our Clients

Our clients trust Yishun Optical for our commitment to excellence and customer satisfaction:

The advanced machines at YISHUN Optical, including diamond lathes and five-axis CNC centers, consistently produce flawless mirror finishes for our high-end projects. Their cutting-edge technology meets our strict standards every time.

YISHUN Optical’s skilled technicians solved our complex polishing challenges with speed and accuracy. Their deep knowledge and problem-solving approach saved us both time and resources on critical orders.

We rely on YISHUN Optical’s strict quality control processes for accurate measurements and consistent outcomes. Every shipment arrives meeting our exact specifications, ensuring a worry-free supply chain.

Blog & Latest Updates

5 Most Common Types of Precision CNC Machining

CNC machining is a general term used for a variety of machining applications. “CNC” stands for Computer Numerical Control and refers to the programmable features of a machine that allow it to perform

How to classify precision machining equipment?

Precision parts machining is the process of creating complex and precise parts, components and objects that we use in our daily lives. Precision machining manufactures parts according to strict tolera

What are the uses of precision machining?

Precision machining can be effectively used to design parts, tools, custom fasteners, and other important hardware. Therefore, parts should have higher tolerances so that they fit precisely with other

Get Started with Your Optical Polishing and Ultra Precision Machining Projects

Ready to take your optical projects to the next level? Yishun Optical is here to support you every step of the way. Our team is dedicated to providing a seamless experience, ensuring that your optical components meet the highest performance standards through our expert polishing and ultra precision machining services.