Home Appliances

Industry Solutions

Elevating Your Products’ Optical Performance and Quality

Where Visual Appeal Meets Functionality in

Premium Home Appliance Markets

In today’s competitive home appliance market, the perfect balance between product appearance and functionality has become key to brand differentiation. Consumer expectations for premium home appliances continue to rise, demanding more aesthetically pleasing and functionally superior products. With 20 years of precision optical and mold manufacturing experience, YISHUN Optical provides comprehensive optical solutions for home appliance manufacturers, helping your products stand out in the marketplace.

Are you facing these home appliance industry challenges?

- Need for high-gloss, perfectly reflective surface finishes

- Precision requirements for high-transparency control panels and display windows

- Consistency and aesthetic demands for complex curved surfaces

- Balance between durability and stylish appearance

- Stringent production timelines and cost control pressures

YISHUN Optical offers specialized optical design, manufacturing, and precision machining services to help you overcome these challenges and create exceptional premium home appliance products.

Our Specialized Home Appliance Industry Solutions

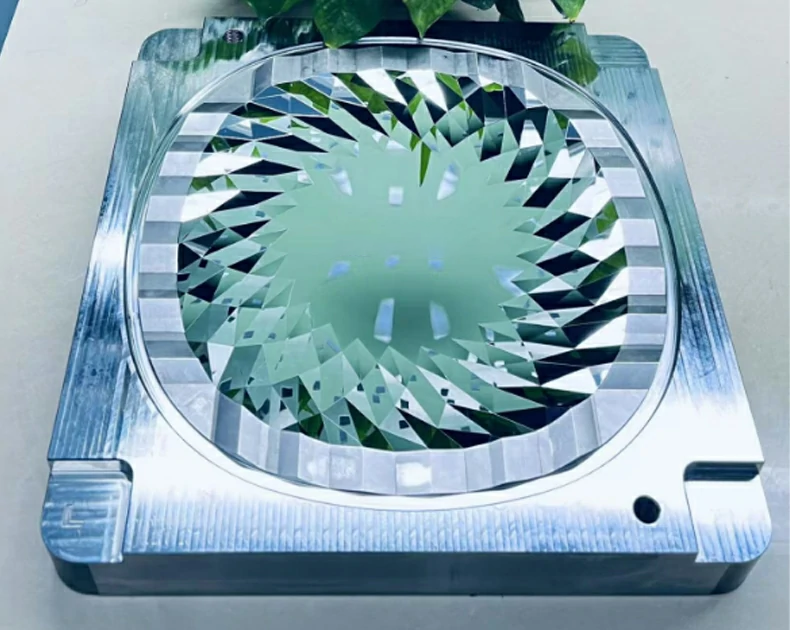

Optical Polishing & Lapping Services - Ultimate Surface Treatment for Appliances

For premium home appliances pursuing perfect surface quality, YISHUN Optical’s specialized polishing and lapping services are essential:

- Mirror Polishing: Providing perfect reflective surface treatments for stainless steel refrigerator panels, glass cooktop surfaces, and premium kitchen equipment.

- Precision Lapping: Ensuring flatness and optical clarity for control panels and displays.

- Textured Surface Treatment: Creating functional surfaces that are fingerprint-resistant and scratch-resistant while maintaining aesthetic appeal.

- Uniform Matte Finishes: Providing even, high-quality matte effects for surfaces requiring low reflectivity.

Our polishing techniques achieve nano-level precision, ensuring your home appliance products make a lasting impression both visually and tactilely on consumers.

Ultra Precision Machining Service

- Superior Manufacturing for Appliance Precision Components

Beyond appearance components, modern home appliances require various high-precision functional components. YISHUN Optical’s ultra precision machining services meet these stringent requirements:

- Precision Control Components: Manufacturing high-accuracy control panels and mechanical parts for smart appliances and IoT devices.

- Optical Lenses and Reflectors: Providing high-quality optical elements for LED lighting, projection, and display systems.

- Precision Connectors: Fabricating dimensionally accurate connectors and interfaces to ensure assembly quality and product durability.

- Micro-Mechanical Parts: Supplying micro-precision components for advanced appliance devices.

Our ultra-precision CNC machining capabilities can achieve tolerances as tight as ±0.5 μm”, ensuring your home appliance products are functionally reliable and performance-exceptional.

Home Appliance Industry Applications

YISHUN Optical’s comprehensive optical solutions have proven their value in various home appliance applications:

Premium Kitchen Appliances

Modern high-end kitchen appliances need to be both beautiful and functional. We provide for these products:

- Mirror polishing treatments for stainless steel surfaces

- Precision molds and polishing for glass control panels

- Optical components for LED displays

- Special treatments for heat-resistant, scratch-resistant surfaces

Smart Appliance Systems

With the evolution of smart home technology, modern appliances require more optical and precision components:

- Transparent molds and polishing treatments for touch panels

- Precision manufacturing of sensor optical components

- Reflective and refractive elements for smart display systems

- Ultra-precision machining of connection components

Premium Washing Machines and Dryers

The surface quality of these large appliances directly influences consumer purchasing decisions:

- High-gloss molds and polishing for front panels

- Transparent windows and indicator designs for control panels

- Machining of internal precision mechanical components

- Anti-corrosion and durability surface treatments

Air Conditioners and Air Purifiers

These products require precision functional components and attractive appearances:

- Precision mold manufacturing for air outlet vanes

- Optical design and polishing for control panels

- Precision machining of internal air duct systems

- High-quality surface treatments for exterior panels

Our Home Appliance Industry Advantagess

Industry Experience

We deeply understand the specific requirements of the home appliance industry:

- 20 years experience in premium home appliance optical solutions

- History of collaboration with internationally renowned appliance brands

- Profound understanding of consumer expectations and market trends

- Expertise in solving complex manufacturing challenges

Quality and Efficiency

We are committed to improving production efficiency without compromising quality:

- ISO-certified quality management systems

- Rigorous quality control processes

- Optimized production scheduling for on-time delivery

- Cost-effective solutions that reduce reject rates

Comprehensive Solutions

YISHUN Optical provides one-stop services from design to manufacturing, ensuring your home appliance products meet the highest standards at every stage:

- Innovative concepts for optical mold design

- Excellence in precision mold manufacturing

- Artistic perfection in surface treatments

- High-precision machining of functional components

Advanced Technology

We continuously invest in state-of-the-art equipment and technologies:

- High-precision CNC and ultra-precision machining centers

- Advanced surface treatment and measurement equipment

- Latest optical simulation and analysis software

- Environmentally controlled production facilities

Benefits of Partnering with YISHUN Optical

Enhanced Brand Image

High-quality optical surfaces and precision components directly elevate the perceived value of your home appliance products, enhancing brand image.

Lower Total Cost of Ownership

Our high-quality molds and precision machining reduce reject rates, extend tool life, and lower long-term production costs.

Accelerated Innovation

Our expertise and technical capabilities enable you to implement innovative designs and features, maintaining competitive advantage in the market.

Production Flexibility

Whether for small-batch premium products or large-scale production, we can provide solutions that meet your needs.

Get Started with Your Optical Polishing and Ultra Precision Machining Projects

Ready to take your optical projects to the next level? Yishun Optical is here to support you every step of the way. Our team is dedicated to providing a seamless experience, ensuring that your optical components meet the highest performance standards through our expert polishing and ultra precision machining services.