Medical

Industry Solutions

Optical Technologies for Enhanced Medical

Device Precision and Quality

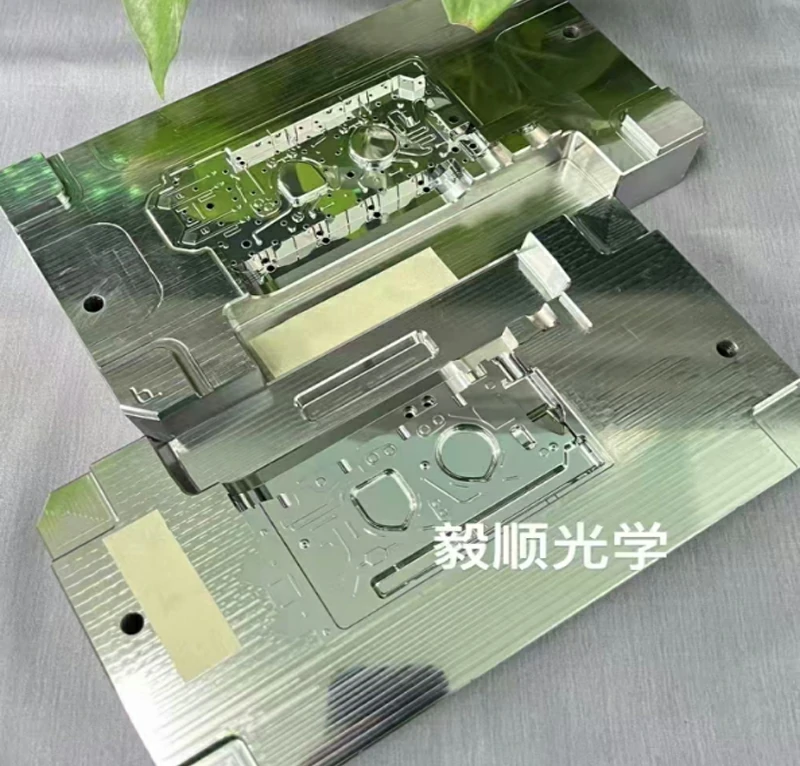

Delivering Superior Optical Mold and Precision Machining Services for Modern Medical Device Manufacturers

In the evolving field of medical technology, precision and reliability are critical factors determining product success. From advanced endoscopes and diagnostic imaging equipment to implantable medical devices and surgical instruments, high-precision optical components and precisely machined parts directly impact treatment efficacy and patient safety. With 20 years of precision optical and mold manufacturing experience, YISHUN Optical provides comprehensive solutions for medical device manufacturers that meet stringent regulatory standards.

Are you facing these medical industry challenges?

- Need for extremely high precision and consistency in optical components

- Strict biocompatibility and material requirements

- Complex regulatory compliance demands and quality validation processes

- Pressure to balance innovative designs with cost-effectiveness

- Precision machining needs for miniaturization and non-invasive instruments

YISHUN Optical combines advanced technology with medical industry expertise to deliver innovative solutions for the most challenging optical and precision machining needs in modern medical devices.

Our Specialized Medical Industry Solutions

Optical Polishing & Lapping Services - Perfect Surface Treatment for Medical Optical Elements

For medical optical components requiring extremely high surface quality, YISHUN Optical’s specialized polishing and lapping services are crucial:

- High-Transparency Surface Treatment: Providing optimal transparency surface treatments for endoscope lenses, microscope optical elements, and diagnostic equipment windows.

- Ultra-Precision Plane Lapping: Ensuring perfect flatness of optical elements suitable for high-precision medical imaging systems.

- Biocompatible Surface Processing: Developing specialized surface treatment processes ensuring the safety of medical devices in direct contact with human tissue.

- Laser Optical Element Polishing: Providing precision optical element surface treatments with high energy tolerance for laser medical devices.

Our polishing techniques achieve nano-level precision with surface roughness as low as Ra 1 nm, ensuring your medical optical components deliver optimal clinical performance.

Ultra Precision Machining Service - Superior Manufacturing for Medical Precision Components

Modern medical devices require various ultra-precision functional parts. YISHUN Optical’s ultra precision machining services meet these stringent requirements:

- Minimally Invasive Surgical Instrument Components: Manufacturing miniature precision components for laparoscopic, arthroscopic, and other minimally invasive surgical tools.

- Implantable Medical Device Parts: Machining high-precision implant components meeting strict biocompatibility requirements.

- Dental and Orthopedic Precision Parts: Providing high-precision machining services for dental implants and orthopedic devices.

- Medical Testing Equipment Components: Manufacturing precision mechanical and optical parts for laboratory and clinical testing equipment.

Our ultra-precision CNC machining capabilities can achieve tolerances as tight as ±0.5 μm”, meeting the most stringent quality and safety standards in the medical industry.

Medical Industry Applications

YISHUN Optical’s comprehensive optical solutions have proven their value in various medical applications

Endoscopes and Minimally Invasive Surgical Devices

Modern endoscopic technology requires extremely precise optical components:

- High-definition miniature camera lens systems

- Complex fiber optic connectors

- Miniature optical illumination systems

- Precision mechanical operation components

Diagnostic and Imaging Equipment

Advanced medical diagnostics rely on high-quality optical systems:

- Precision optical elements for MRI and CT equipment

- Biosensor optical components

- Microscopy imaging system lenses

- Optical biomarker detection devices

Laser Medical Instruments

Medical laser systems require specialized optical solutions:

- High-precision laser focusing systems

- Energy transmission optical elements

- Laser beam shaping and control components

- Medical laser safety systems

Implantable and Wearable Medical Devices

Modern medical technology trends toward miniaturization and intelligence:

- Biosensor optical windows

- Precision components for miniature monitoring devices

- Optical communication systems for smart implants

- Precision structural components for wearable devices

Our Medical Industry Advantages

Comprehensive Compliance

YISHUN Optical understands the strict requirements of the medical industry:

- Compliance with ISO 13485 medical device quality management systems

- Strict material traceability and documentation management

- Complete verification and validation processes

- Manufacturing processes compliant with FDA and CE regulatory requirements

Specialized Medical Knowledge

Our team has extensive experience in medical device manufacturing:

- Understanding of specialized optical requirements for medical devices

- Familiarity with biocompatibility and safety standards

- Knowledge of medical certification and validation processes

- Ability to work closely with medical device engineers

Superior Precision

Our manufacturing capabilities meet the extremely high standards of the medical industry:

- Nano-level surface precision

- Micron-level dimensional tolerances

- Consistent batch production quality

- Advanced inspection and quality control systems

Innovative R&D Capabilities

We continuously advance medical optical technology:

- Focus on miniaturized optical solutions

- Development of new biocompatible material applications

- Innovative optical designs improving diagnostic and treatment efficacy

- Optimized manufacturing processes reducing costs

Benefits of Partnering with YISHUN Optical

Enhanced Product Performance

Our high-precision optical and precision-machined components directly improve the diagnostic accuracy and treatment efficacy of your medical devices.

Accelerated Regulatory Approval

Our comprehensive quality systems and documentation management help your products navigate regulatory approval more smoothly.

Reduced Development Risk

Our expertise and experience reduce design errors and manufacturing issues, lowering development risk.

Optimized Total Cost of Ownership

Our high-quality components extend product lifespan, reduce maintenance requirements, and lower long-term costs.

Get Started with Your Optical Polishing and Ultra Precision Machining Projects

Ready to take your optical projects to the next level? Yishun Optical is here to support you every step of the way. Our team is dedicated to providing a seamless experience, ensuring that your optical components meet the highest performance standards through our expert polishing and ultra precision machining services.