Automotive

Industry Solutions

Enhancing Precision and Quality of Automotive Optical Components

Delivering Superior Optical Mirror Polishing and Precision Machining Solutions for Modern Automotive Manufacturers

In today’s rapidly evolving automotive market, optical quality and precision components have become critical factors determining product excellence. From advanced headlight systems to precision dashboards, from touch screens to optical elements for Advanced Driver Assistance Systems (ADAS), YISHUN Optical provides comprehensive solutions helping automotive manufacturers and Tier 1 suppliers achieve higher standards of precision and quality.

Are you facing these automotive industry challenges?

- Demand for complex optical components with high reflectivity and transparency requirements

- Stringent safety standards and durability requirements

- Increasingly sophisticated lighting systems and display interface designs

- Pressure to balance high quality with cost-effectiveness

- Need to accelerate innovation cycles and reduce time-to-market

YISHUN Optical combines advanced technology with 20 years of industry experience to deliver innovative solutions for the most challenging optical and precision machining needs in modern automotive manufacturing.

Our Specialized Automotive Industry Solutions

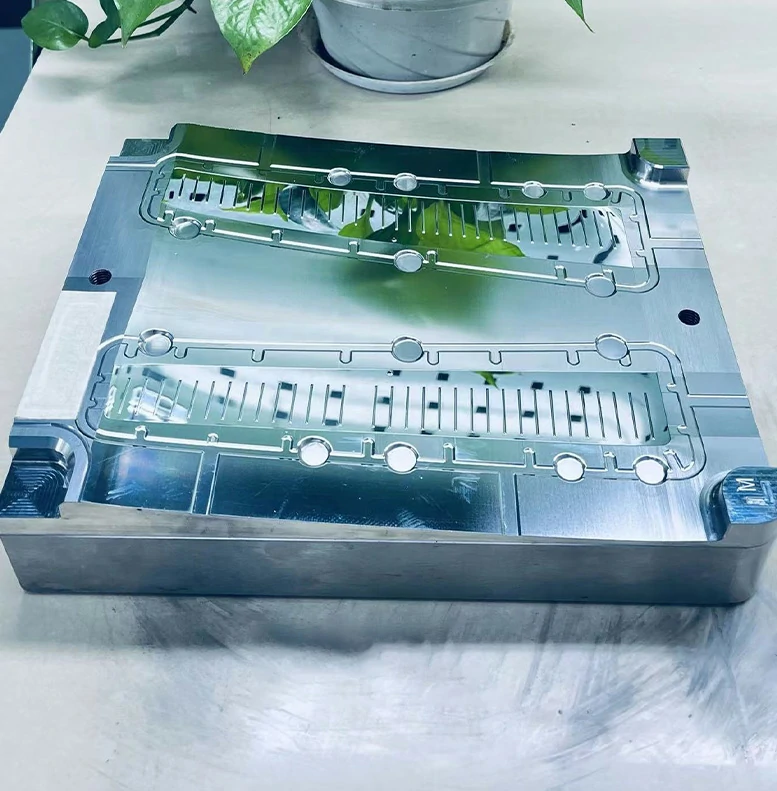

Optical Polishing & Lapping Services - Ultimate Surface Treatment for Automotive Optical Components

For automotive optical components requiring perfect surface quality, YISHUN Optical’s specialized polishing and lapping services are crucial:

- High-Reflectivity Surfaces: Providing perfect reflectivity surface treatments for headlight reflectors and optical sensors.

- Transparent Element Polishing: Ensuring optical clarity and transparency for heads-up displays, instrument panel covers, and touch screens.

- Functional Surface Treatments: Creating precision surfaces with anti-glare, anti-reflective, or specific light-scattering characteristics.

- Complex Shape Polishing: Our techniques can process optical components with complex geometries while maintaining precise surface quality.

Our polishing techniques achieve nano-level precision, ensuring your automotive optical components deliver superior performance and durability.

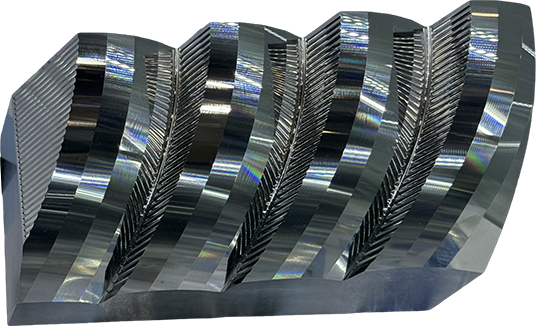

Ultra Precision Machining Service - Advanced Manufacturing for Automotive Precision Components

Modern vehicles require various high-precision functional parts. YISHUN Optical’s ultra precision machining services meet these stringent requirements:

- Optical Sensor Components: Manufacturing high-precision optical elements for LiDAR, cameras, and radar systems.

- Precision Mechanical Parts: Providing high-accuracy mechanical components for steering, braking, and powertrain systems.

- Electric Vehicle Components: Delivering precision parts for battery management systems and electrification components.

- Connectors and Interfaces: Fabricating high-precision connectors and interfaces ensuring reliability in electronic systems.

Our ultra-precision CNC machining capabilities can achieve tolerances as tight as ±0.5μm”, meeting the most stringent quality and safety standards in the automotive industry.

Automotive Industry Applications

YISHUN Optical’s comprehensive optical solutions have proven their value in various automotive applications

Advanced Lighting Systems

Modern automotive lighting requires precise optical design and manufacturing:

- Precision reflectors and lenses for LED and laser headlights

- Optical control elements for adaptive lighting systems

- Optical distribution systems for daytime running lights and indicators

- Light-guide elements for interior ambient lighting

Driver Assistance Systems

ADAS and autonomous driving technologies rely on high-quality optical components:

- Optical elements for LiDAR and camera systems

- Precision transparent components for sensor windows and protective covers

- Specialized optical designs for night vision systems

- Wide-angle optical elements for surround-view monitoring systems

In-Vehicle Infotainment Systems

User interfaces and display systems require excellent optical quality:

- Transparent protective panels for dashboards and central display screens

- Precision projection optical systems for heads-up displays

- Optical bonding and surface treatments for touch screens

- Backlighting systems for buttons and control interfaces

Body and Interior Components

Exterior and interior parts also require high-quality surface treatments:

- Mirror polishing for premium decorative trim

- Precision surfaces for reflective emblems and badges

- Surface treatments for interior mirrors and decorative panels

- Special optical effect elements for high-end vehicle models

Our Automotive Industry Advantages

Comprehensive Solutions

YISHUN Optical provides one-stop services from design to manufacturing:

- Specialized optical design and simulation capabilities

- High-precision mold manufacturing technologies

- Cutting-edge surface treatment processes

- Advanced quality control and testing systems

Automotive Industry Expertise

We deeply understand the specific requirements of the automotive industry:

- 20 years of automotive optical component experience

- Familiarity with IATF 16949 and industry standards

- Close collaboration with Tier 1 automotive suppliers

- Profound understanding of future automotive technology trends

Superior Quality and Reliability

We are committed to delivering solutions that meet the stringent standards of the automotive industry:

- Comprehensive quality management systems

- Rigorous material selection and testing processes

- Extensive product validation and certification

- Reliable production techniques and process controls

Innovation Capability

We continuously push the boundaries of automotive optical technology:

- Researching new optical structures and materials

- Optimizing production processes for greater efficiency

- Developing innovative surface treatment technologies

- Advanced optical simulation and testing methodologies

Benefits of Partnering with YISHUN Optical

Enhanced Product Performance

Our high-precision optical components directly improve the performance, safety, and user experience of your automotive products.

Accelerated Development Cycles

Our expertise and efficient development processes help you bring innovative products to market faster.

Enhanced Product Performance

Our high-precision optical components directly improve the performance, safety, and user experience of your automotive products.

Accelerated Development Cycles

Our expertise and efficient development processes help you bring innovative products to market faster.

Get Started with Your Optical Polishing and Ultra Precision Machining Projects

Ready to take your optical projects to the next level? Yishun Optical is here to support you every step of the way. Our team is dedicated to providing a seamless experience, ensuring that your optical components meet the highest performance standards through our expert polishing and ultra precision machining services.