Ultra Precision Machining Service

Our cutting-edge technology achieves tolerances as low as ±0.5μm and surface roughness as low as Ra 1nm, making us the preferred partner for industries demanding ultimate precision.

Engineering Solutions with Nano-Level Accuracy

In today’s competitive high-tech manufacturing landscape, precision differences can determine product success or failure. With 20 years of ultra-precision machining experience, YISHUN Optical provides industry-leading nano-level precision machining services, solving the most challenging precision manufacturing needs for clients worldwide. Our cutting-edge technology achieves tolerances as tight as ±0.5μm” and surface roughness as low as Ra 1 nm, making us the partner of choice for industries where ultimate precision is non-negotiable.

Are you facing these challenges?

- Optical or precision mechanical components requiring extreme accuracy and surface quality

- Complex geometries needing ultra-precise machining

- High-precision requirements for difficult-to-machine materials

- Production needs under strict tolerance requirements

- Optical-grade surface quality requirements

YISHUN Optical has the state-of-the-art equipment, technical expertise, and experienced engineers to provide comprehensive ultra-precision machining solutions, no matter how complex your project or how stringent your requirements.

Our Ultra Precision Machining Capabilities

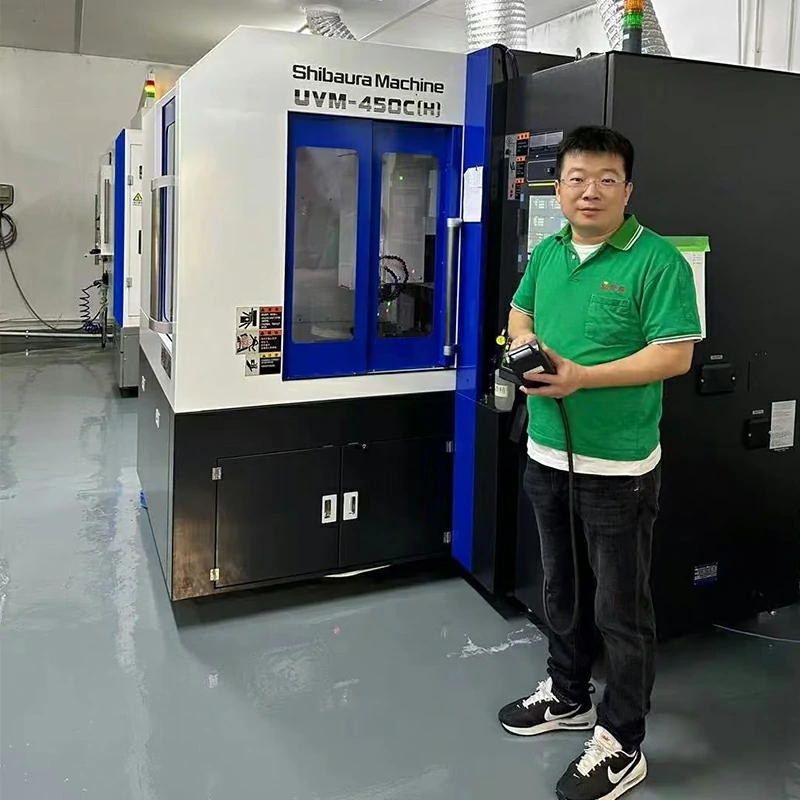

Ultra Precision CNC Machining

Computer Numerical Control (CNC) machining is a manufacturing process where advanced computer software controls various machines to produce precise parts and components. With our customized CNC machining services, we can complete three-dimensional cutting tasks in a single operation with exceptional repeatability.

At YISHUN Optical, we combine advanced technology with over 20 years of expertise in CNC programming to deliver high-precision machining services. Our facilities are equipped with cutting-edge machines like Mohr diamond lathes and ABB six-axis robots, ensuring that each part is crafted with meticulous attention to detail. Whether you need a single piece or large-volume production, we deliver parts with the precision your project demands.

With our multi-axis CNC machining capabilities, YISHUN Optical can produce complex components with extremely tight tolerances. Our high-speed CNC centers and advanced equipment allow us to achieve tolerances as tight as ±0.5μm” and positional tolerances of ±1μm” or better.

Our Technological Advantagesents

YISHUN Optical employs multiple advanced processes to provide the optimal solution for your specific needs.

Ultra Precision Turning

Ultra precision turning is a process that uses high-precision CNC lathes to machine precision parts, particularly suited for optical components and precision axisymmetric parts. YISHUN Optical’s ultra precision turning services utilize state-of-the-art Mohr diamond lathes capable of achieving:

- Surface roughness down to Ra 1 nm

- Form accuracy controlled within 0.1 μm

- Dimensional tolerances achieving ±0.5 μm

- Perfect axisymmetric component machining

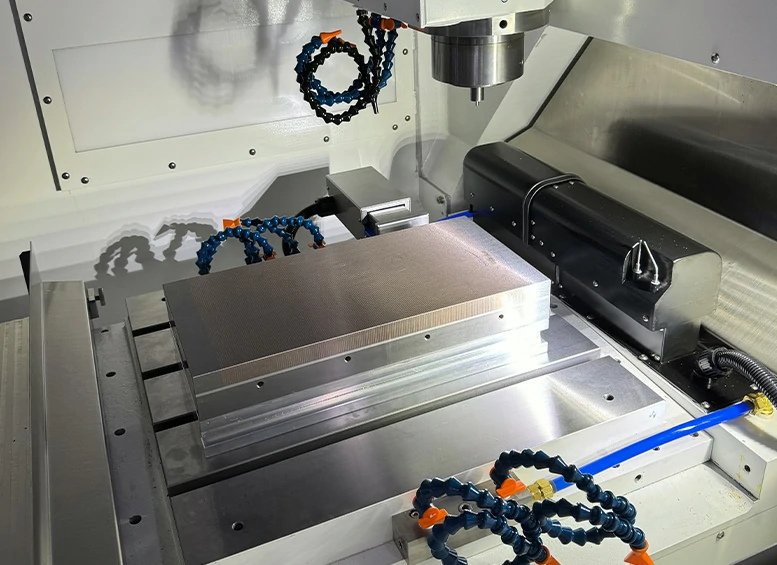

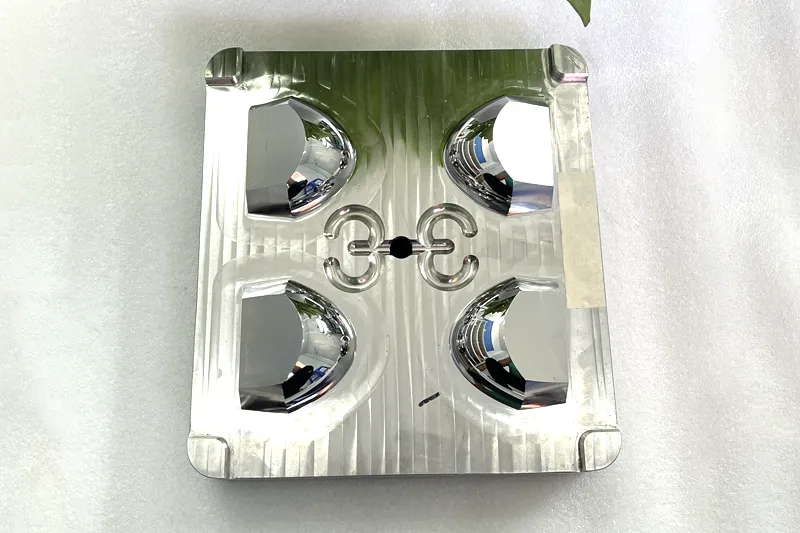

Ultra Precision Milling

Ultra precision milling is ideal for handling complex three-dimensional shapes, particularly for molds, optical components, and precision mechanical parts. Our ultra precision milling services provide:

- High-accuracy machining of complex shapes

- Fine surface quality

- Precise manufacturing of micro-features

- Precision machining of high-hardness materials

Ultra Precision Grinding

For applications requiring extreme surface quality and dimensional accuracy, our ultra precision grinding services are the perfect choice. This process is particularly suited for hard materials and components requiring strict tolerances. We offer:

- Surface and profile grinding

- Internal and external cylindrical grinding

- Centerless grinding

- Precision honing

The Advantages of Ultra Precision Technology

YISHUN Optical’s ultra precision machining services offer several distinct advantages

Materials We Process

YISHUN Optical has expertise in handling a wide range of advanced materials

Metals

- Stainless Steel, Superalloys, Copper, Titanium

- Aluminum, Exotic alloys (including Invar and Kovar)

- Tungsten, Nickel, and more

- HRC48 52 degrees heat treated mold steel

Plastics and Composites

- PEEK (Polyether Ether Ketone)

- PMMA (Polymethyl Methacrylate)

- High-performance engineering plastics

Application Areas

Our ultra precision machining services meet the needs of multiple high-tech industries

Optical Components

- Precision lenses and prisms

- High-reflectivity mirrors

- Optical molds and tooling

- Beam-shaping elements

Precision Molds

- Injection mold mirror surfaces

- Precision stamping dies

- Optical molds

- Micro-mold components

Precision Mechanical Parts

- High-precision five-axis machining

- Precision positioning system components

- Precision medical device parts

Metrology and Testing Equipment

- Precision reference components

- Measurement standards

- Measuring probes and sensors

- Calibration equipment

Industry Solutions

YISHUN Optical’s ultra precision machining services meet the needs of multiple industries

Ultra Precision Machining Techniques

YISHUN Optical employs multiple cutting-edge techniques to achieve ultra precision machining

Equipment Advantage

Our facility is equipped with state-of-the-art ultra precision machining equipment

Mohr Diamond Lathes

- Nano-level surface finishes

- Sub-micron form accuracy

- Optical-grade surface quality

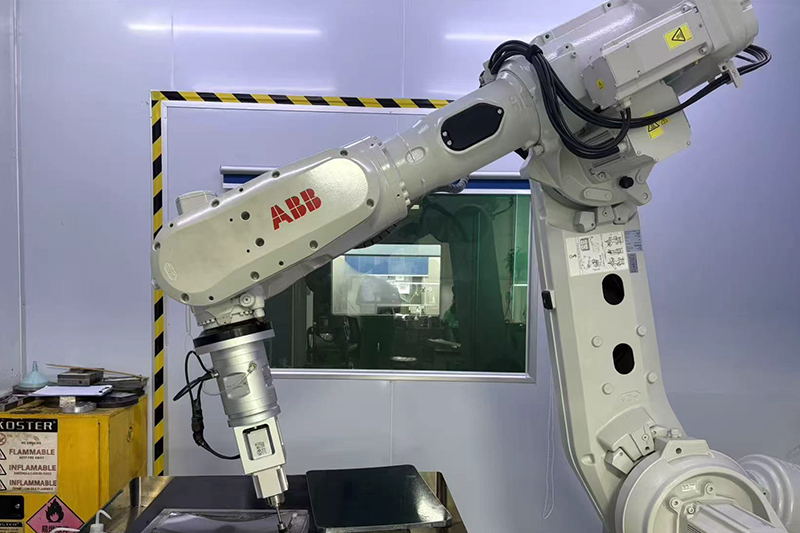

ABB Six-Axis Robots

- Automated precision operations

- Consistent quality control

- Enhanced production efficiency

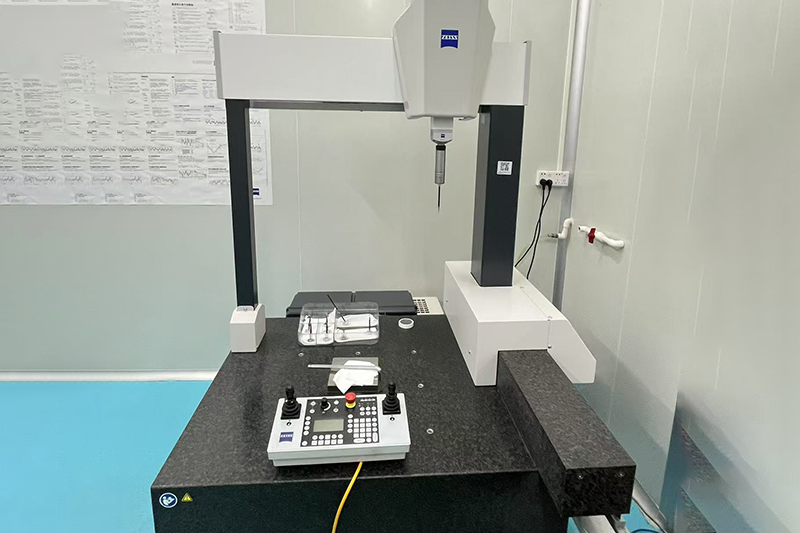

ZYGO

- Zeiss and Zygo measurement systems

- Interferometers and profilometers

- Atomic Force Microscope inspection

Low Volume Ultra Precision Machining Services

At YISHUN Optical, we specialize in low-volume ultra precision machining with tight tolerances, handling production runs ranging from hundreds to thousands of parts per year. Our efficient systems allow for extended production runs with minimal setup, ensuring quicker turnaround times and cost-effective manufacturing.

Our CNC machines are equipped with pallet systems that allow for continuous production, with automatic material loading and unloading, which keeps the machining process running smoothly 24/6.

Why Choose YISHUN Optical for Custom Ultra Precision Machined Parts?

Our ultra-precision machining services offer exceptional accuracy and repeatability. Whether you need custom parts for optical components or intricate mold polishing, our machines deliver ultra-sharp cuts and tight tolerances for optimal performance. Some of the key benefits of working with us include:

- Precision and accuracy at the nano level

- High repeatability for consistent results

- Capability to meet extremely tight tolerances

- Suitable for the most demanding engineering applications

- Cost-effective for complex geometries

- Fast production turnaround, getting your products to market quickly

Value-Added Services

In addition to ultra precision machining, we offer a range of value-added services to ensure the best results for your project. These services include:

- Custom mirror surface processing

- Ultra precision optical polishing

- In-house tool and die manufacturing

- Precision measurement using Zeiss and Zygo systems

- Comprehensive quality documentation

- Assembly and integration services

Quality Assurance

YISHUN Optical’s commitment to quality is evident in every step of our process

Inspection Equipment

- Surface Roughness Testers: Measuring to nanometer levels

- Flatness Interferometers: Measuring flatness to fractions of a wavelength

- Roundness Testers: For precision spherical components

- Coordinate Measuring Machines: For dimensional verification

Quality Procedures

- Initial inspection of incoming materials

- In-process inspection at critical stages

- Final inspection with comprehensive documentation

- Traceable records for each component

Certifications

- ISO 9001:2015 Quality Management System

- ISO 14001:2015 Environmental Management System

- Compliance with industry-specific standards

Why Choose YISHUN Optical?

Advanced Technology and Equipment

- Latest ultra precision machining machines

- Advanced metrology and quality control systems

- Environmentally-controlled clean room facilities

Material Expertise

- Experience with a vast range of materials from soft metals to hard crystals

- Specialized knowledge to address unique material challenges

- Comprehensive understanding of material characteristics

Quality Commitment

- ISO standard certifications

- Comprehensive testing and verification

- Rigorous quality control processes

Extensive Experience

- 20 years of ultra precision machining experience

- Success stories across multiple high-tech industries

- Expertise in solving complex machining challenges

Customer -Centric Approach

- Customized solutions tailored to your specific application

- Responsive service and flexible production capabilities

- Long-term partnership relationships

How Our Customers Benefit

Enhanced Product Performance

Our ultra precision machining translates directly into better product performance, whether it's optical clarity, mechanical durability, or overall functionality.

Cost Reduction

By manufacturing precisely the first time, we reduce scrap rates, lower rework costs, and extend tool life.

Competitive Advantage

When your products showcase the highest quality precision machining, you stand out in the marketplace, attracting high-value customers and building a reputation for excellence.

Complex Challenge Resolution

Our expertise enables you to develop and manufacture innovative products that were previously impossible due to machining limitations.

Get Started with Your Optical Polishing and Ultra Precision Machining Projects

Ready to take your optical projects to the next level? Yishun Optical is here to support you every step of the way. Our team is dedicated to providing a seamless experience, ensuring that your optical components meet the highest performance standards through our expert polishing and ultra precision machining services.