Precision parts machining is the process of creating complex and precise parts, components and objects that we use in our daily lives. Precision machining manufactures parts according to strict tolerances so that they can be specifically and accurately installed on the object or machine being manufactured. Because precision machining requires such precision, the materials and processing equipment used for precision machining must also be very precise. Here, we look at some of the most common processing equipment in precision machining

Overview of precision machining equipment

Generally speaking, precision machining tasks can be divided into milling, turning and boring. Precision machining focuses on creating a part or object by subtracting material, rather than adding material to create the correct shape. In some cases, cutting processes also fall into the field of precision machining.

Milling involves using cutting and grinding tools to remove material to create a part. Turning rotates the material and uses cutting tools to shape and modify the part. The function of a boring machine is to drill holes in the material using precise rotating cutting tools. The following precision machining equipment belongs to one of the above categories.

Automatic Lathe

Officially known as the Swiss Lathe, the Swiss Lathe was originally used to make parts for Swiss watches that were very small, just a few millimeters in diameter. Automatic Lathes are very effective at machining small and elongated parts without causing displacement or vibration. It does this by holding the workpiece in place while the tool rotates around it. Automatic Lathes can also be modified to accurately manufacture parts of special shapes. Today, high-specification Swiss machines can machine extremely complex shapes and extremely accurate dimensions on 9 axes.

CNC Lathe

A lathe is a precision machining tool that rotates the workpiece relative to the cutting tool. Today, the vast majority of lathes in a machine shop are CNC lathes, which are computer-controlled and have multi-axis machining capabilities, allowing them to efficiently machine accurately shaped turned parts. CNC lathes have a fairly wide range of machining, generally machining parts with diameters ranging from 1.5 to 550 mm.

Milling Machine

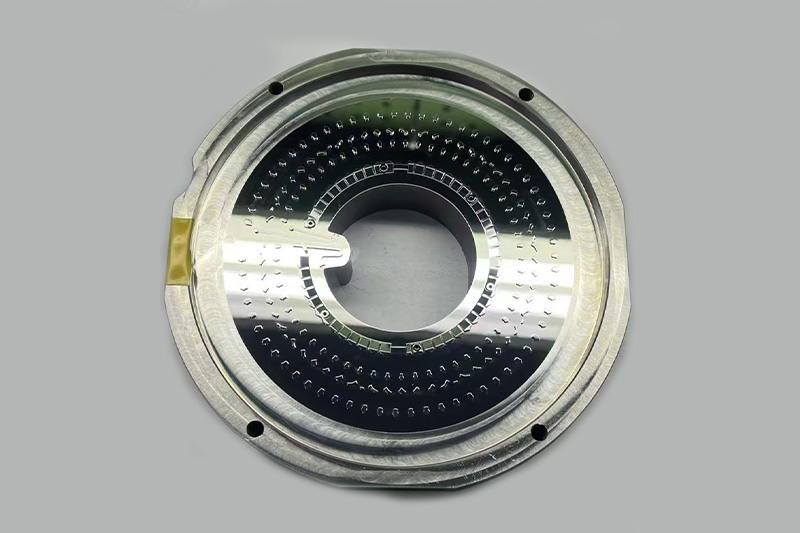

Milling machines can be vertical or horizontal, depending on the spindle, and are generally used to cut, shape and grind materials to size. In a milling machine, both the workpiece and the tool are moved to form the desired shape and size. Because heat and friction are generated during the operation of a precision milling machine, cutting fluids, lubricants, and coolants can be used to produce the most precise and uniform machining. Spindle coolers can also be used to help maintain machine accuracy and avoid temperature fluctuations that affect workpiece dimensions.

Electrical Discharge Machining Equipment

Electrical Discharge Machining Equipment (EDM) is used to cut metals that conduct electricity. EDM machines use an electrically charged wire or electrode to cut or punch metal. There are two main types of EDM machines – wire EDM and sinker EDM. EDM machines use wires to cut metal to obtain the desired shape. In sinker EDM, a power source creates sparks between the electrode and the metal, which cuts the metal. Electrodes can be designed and manufactured in-house by precision machining companies to achieve the exact requirements required.

Laser Engraving

Laser engraving is another way to make precise marks and cuts on metals for precision machining. The laser is mounted on a rotating attachment that allows for the flexibility of etching or engraving the part. Laser engraving can be used on aluminum or plastics and can be used to mark medical tools. Laser engraving can also add an important aspect to precision engineering, allowing custom logos, serialization and QR codes to be printed on parts or products.