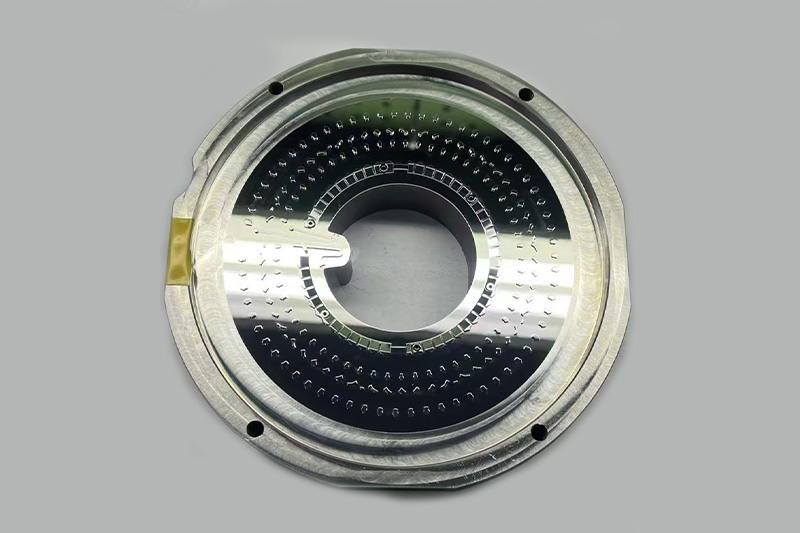

Precision machining can be effectively used to design parts, tools, custom fasteners, and other important hardware. Therefore, parts should have higher tolerances so that they fit precisely with other components.

An interesting fact is that precision machining maintains the reliability of mass-produced parts. This is especially noticeable when producing accessories. Precision machine parts manufacturers ensure that constant and repeatable results are obtained.

Also, precision machining can be felt in the finishing of metal products. For example, you can use precision machining to finish parts produced through die casting or less precise manufacturing techniques. Conversely, precision machining has its uses in restoration work.

Also, worn parts may need to be grooved, welded, or calibrated over a period of time, so computer-aided equipment will restore the parts to their original condition.

Why choose precision machine components for your project?

There are many reasons to choose precision machining, as it is the best process in international manufacturing.

Let us review the advantages of precision machining:

1. Highest level of precision

The smallest millimeter can make a difference in the global manufacturing industry, especially in the medical electronics industry. Due to this reason, precision machining is a top priority in this industry. Every manufacturer needs precise specifications and drawings, and the preparation of CNC machines for precise cutting.

2. Less waste of raw materials

Although precision machining has subtractive manufacturing, it produces more material waste than additive manufacturing, but it reduces the error rate and improves quality. This reduces the waste of inferior products or repeated procedures and uses more materials.

In addition, precision machined parts successfully reduce the waste of raw materials because cutting parts brings high precision. We know that raw materials such as graphite, copper, steel and plastic are expensive, and any waste is unacceptable.

3. Fast assembly

Precision machines automatically set up components without manual interruption of assembly. Since the process is fast and automated, production time is greatly reduced.

4. Cost-effective

With fewer errors and the highest output, precision machining can greatly reduce manufacturing costs. It enables manufacturers to make appropriate production financial plans and reduce labor expenses.

5. Safe production

Accidents are the most common thing in the manufacturing industry. According to the US Bureau of Statistics, there are 303 serious work injuries in the manufacturing industry. Mechanical accidents are painful, but their occurrence is reduced due to the automated procedures of precision machining.

6. Efficient and fast production

Since computers control precision machined parts and own every detail of the production procedure, they can produce results efficiently and quickly.

7. No human involvement required

With precision machined parts, there is no tendency for human error, resulting in rich results.